D.I.P Howa Mini Bottom Metal & Magazine Accessories Review and Test [2019]

DIP billet aluminum bottom metal paired with a flush-fit magazine

Bottom Line Up Front (BLUF)

The DIP bottom metal takes the Howa Mini from "pretty neat gun" to "field-grade heirloom" in one move. It adds only 1.5 oz. to the overall rifle's weight, but being milled from solid aluminum billet, it's virtually indestructible. At around $120 it's a pricey upgrade, but adding $120 to the Howa Mini's purchase price still puts it at/below the price points of much of the competition, and it turns the Howa Mini into the real deal – an all-metal bolt-action that can be counted on, no matter what.

In addition to the bottom metal, DIP manufactures a magazine release and magazine baseplate for the Howa Mini – here are the BLUFs for them:

The DIP mag release is a well-made part and it does lower the profile of the magazine release significantly, but we’d only call it a necessity for serious excursions into deep bush, where accidental magazine drops due to stray branches or vines pose a constant threat.

The DIP magazine baseplate makes your magazine all but indestructible, but it’s well over half the cost of the magazine itself, so while we’d recommend buying one, maybe don’t feel obligated to upgrade every Howa Mini magazine that you own. The baseplate is necessary to craft a flush-fit magazine for your DIP bottom metal, although it's not needed for a flush-fit magazine on the factory (plastic) bottom metal.

In addition to the bottom metal, DIP manufactures a magazine release and magazine baseplate for the Howa Mini – here are the BLUFs for them:

The DIP mag release is a well-made part and it does lower the profile of the magazine release significantly, but we’d only call it a necessity for serious excursions into deep bush, where accidental magazine drops due to stray branches or vines pose a constant threat.

The DIP magazine baseplate makes your magazine all but indestructible, but it’s well over half the cost of the magazine itself, so while we’d recommend buying one, maybe don’t feel obligated to upgrade every Howa Mini magazine that you own. The baseplate is necessary to craft a flush-fit magazine for your DIP bottom metal, although it's not needed for a flush-fit magazine on the factory (plastic) bottom metal.

Review Contents

This review is organized as shown below. You can read the whole thing, or just use the below guide to find to the section that’s most interesting to you.

- DIP Howa Mini Bottom Metal Overview

- Tabletop Handling Observations

- In the field

- Wrap up

D.I.P How Mini Bottom Metal Overview

The Howa Mini is a great rifle priced substantially lower than many of its competitors, despite ritzy features such as a flat-bottomed receiver, integral recoil lug, one-piece bolt, and a 3-position safety. However, all that value does mean certain tradeoffs and one of the spots where the Howa Mini cut corners is the all-plastic 'bottom metal' (aka magazine well). Disassembled, the plastic bottom metal feels chintzy in the hand, and we doubt that it could take too many hard drops in cold weather before it cracked. The receiver screw tangs also get beat up pretty quickly when torquing down on the action screws to the recommended 55 in/lbs.

In short, the plastic bottom metal prevents the Howa Mini from being a truly great gun, but the good news is that there are two manufacturers (as of this writing) producing aluminum bottom metal for the Howa Mini. One of them is Diversified Innovative Products (DIP) and their bottom metal ditches the factory plastic construction in favor of billet-machined aluminum, as well as featuring a few small fixes to other rough spots in the factory Howa design. We felt that this was a smart approach, and DIP was kind enough to send us their bottom metal to tinker with. They also sent along some of their other Howa Mini goodies, so let’s start breaking it down.

In short, the plastic bottom metal prevents the Howa Mini from being a truly great gun, but the good news is that there are two manufacturers (as of this writing) producing aluminum bottom metal for the Howa Mini. One of them is Diversified Innovative Products (DIP) and their bottom metal ditches the factory plastic construction in favor of billet-machined aluminum, as well as featuring a few small fixes to other rough spots in the factory Howa design. We felt that this was a smart approach, and DIP was kind enough to send us their bottom metal to tinker with. They also sent along some of their other Howa Mini goodies, so let’s start breaking it down.

Tabletop Handling Observations

The DIP bottom metal adds only 1.5 oz. to the overall rifle's weight (about equivalent to a handful of paper clips), but being milled from solid aluminum billet, it’s virtually indestructible. It's precisely milled, dropping right in with zero fitting required, and all our magazines drop free in the DIP bottom metal just like from the factory unit. The DIP bottom metal’s fit in the stock is a hair tighter than the factory bottom metal - it's still drop-in, but for those who have glass-bedded their stocks, you might need to spend a few minutes sanding, and then consider skim bedding once everything fits again.

The headliner of the DIP bottom metal is of course its billet aluminum construction – if you want your Howa Mini by your side, no matter what, then you need to ditch the flimsy plastic bottom metal. However, the DIP bottom metal doesn’t stop at aluminum construction, adding two more unique bonuses to round out the package:

First, the DIP bottom metal adds just a bit of extra tension to the spring on the mag release, which makes the mag release lever about twice as stiff. It’s still easy to operate, just much less likely to accidentally drop the mag when you brush the lever with your support hand (shortening the lever is still recommended to prevent accidental mag drops, or you could opt for DIP's own re-designed mag release – more on that below).

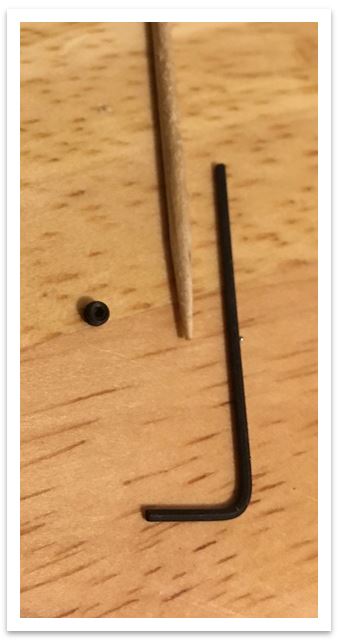

Second, the DIP bottom metal adds a fix to the mag release roll pin. The roll pin on the factory bottom metal is held in place by friction only - if it backs out, your mag release is lost. While this is a rare problem, DIP still went ahead and added the teeny tiniest grub screw you've ever laid eyes on. Tighten the grub screw on the mag release roll pin after install, and you're good from now until the end of days.

The headliner of the DIP bottom metal is of course its billet aluminum construction – if you want your Howa Mini by your side, no matter what, then you need to ditch the flimsy plastic bottom metal. However, the DIP bottom metal doesn’t stop at aluminum construction, adding two more unique bonuses to round out the package:

First, the DIP bottom metal adds just a bit of extra tension to the spring on the mag release, which makes the mag release lever about twice as stiff. It’s still easy to operate, just much less likely to accidentally drop the mag when you brush the lever with your support hand (shortening the lever is still recommended to prevent accidental mag drops, or you could opt for DIP's own re-designed mag release – more on that below).

Second, the DIP bottom metal adds a fix to the mag release roll pin. The roll pin on the factory bottom metal is held in place by friction only - if it backs out, your mag release is lost. While this is a rare problem, DIP still went ahead and added the teeny tiniest grub screw you've ever laid eyes on. Tighten the grub screw on the mag release roll pin after install, and you're good from now until the end of days.

We just want to take a moment to convey how small this grub screw is.

For scale, the tan rod is the end of a toothpick, used as a capture pin during install of the magazine release.

For scale, the tan rod is the end of a toothpick, used as a capture pin during install of the magazine release.

D.I.P Magazine Release and Magazine Baseplate

Beyond the bottom metal, DIP makes their own mag catch lever from billet aluminum, just for the Howa Mini. The factory Howa Mini magazine lever is notorious – since the lever is mounted in front of the magazine well, it’s awfully easy to hit with your support hand by accident, so it doesn’t take much more than a mean look to release the magazine.

The DIP mag catch fixes this issue by requiring a downward stroke to operate, rather than a backward stroke. This means that accidentally bumping the lever with your hand won’t do anything.

The DIP mag catch fixes this issue by requiring a downward stroke to operate, rather than a backward stroke. This means that accidentally bumping the lever with your hand won’t do anything.

The factory mag lever extends slightly below a flush-fit magazine, although it can easily be shortened with a few minutes and a file.

The factory lever moves straight backward, making it vulnerable to being bumped by your support hand or dense underbrush.

The factory lever moves straight backward, making it vulnerable to being bumped by your support hand or dense underbrush.

The DIP mag lever is extremely low profile and its front lip must be pulled downward to drop the magazine,

rather than being pushed backward like the factory lever. This minimizes the risk of a bump turning into an accidental mag drop.

rather than being pushed backward like the factory lever. This minimizes the risk of a bump turning into an accidental mag drop.

The DIP mag catch is all but impossible to hit accidentally, and it's still easy to operate, even wearing thick gloves (for that winter-time shooting we all pretend we're going to do). However, as we mentioned before, it is worth noting that the factory magazine lever is made about twice as stiff after you install the DIP bottom metal. Add in a few minutes with a file to shorten the lever a bit, and you’ve got a decently bump-resistant magazine catch without spending extra money. The DIP magazine catch is a quality part and highly recommended for hunting in dense brush, where branches and vines constantly threaten the Mini’s magazine, but we wouldn’t call it a necessity for most shooters.

As previously mentioned, DIP also makes an aluminum magazine baseplate. This part makes the magazine invulnerable to drops onto concrete or rocks (an especially risky activity in wintertime), and it also resolved the one hiccup we had with the DIP bottom metal’s fitment: if you're not familiar, it's fairly straightforward to take a factory Howa Mini magazine and cut it down, making it fit flush with the magwell and keeping the magazine from gouging into your back as you hike through the backcountry. This worked fine on the factory plastic bottom metal, but the DIP bottom metal would not let our handmade, cut-down magazine seat all the way - we guess that the DIP magwell extends just slightly farther down the side of the magazine than the factory magwell.

The good news is that DIP’s aluminum magazine baseplate is just a hair shorter than the factory plastic baseplate and it lets the cut-down mag fit just fine. Note that this is ONLY an issue if you are using a cut-down magazine - plain factory magazines fit and function without any issues at all and don’t need any special parts or attention.

As previously mentioned, DIP also makes an aluminum magazine baseplate. This part makes the magazine invulnerable to drops onto concrete or rocks (an especially risky activity in wintertime), and it also resolved the one hiccup we had with the DIP bottom metal’s fitment: if you're not familiar, it's fairly straightforward to take a factory Howa Mini magazine and cut it down, making it fit flush with the magwell and keeping the magazine from gouging into your back as you hike through the backcountry. This worked fine on the factory plastic bottom metal, but the DIP bottom metal would not let our handmade, cut-down magazine seat all the way - we guess that the DIP magwell extends just slightly farther down the side of the magazine than the factory magwell.

The good news is that DIP’s aluminum magazine baseplate is just a hair shorter than the factory plastic baseplate and it lets the cut-down mag fit just fine. Note that this is ONLY an issue if you are using a cut-down magazine - plain factory magazines fit and function without any issues at all and don’t need any special parts or attention.

In the field

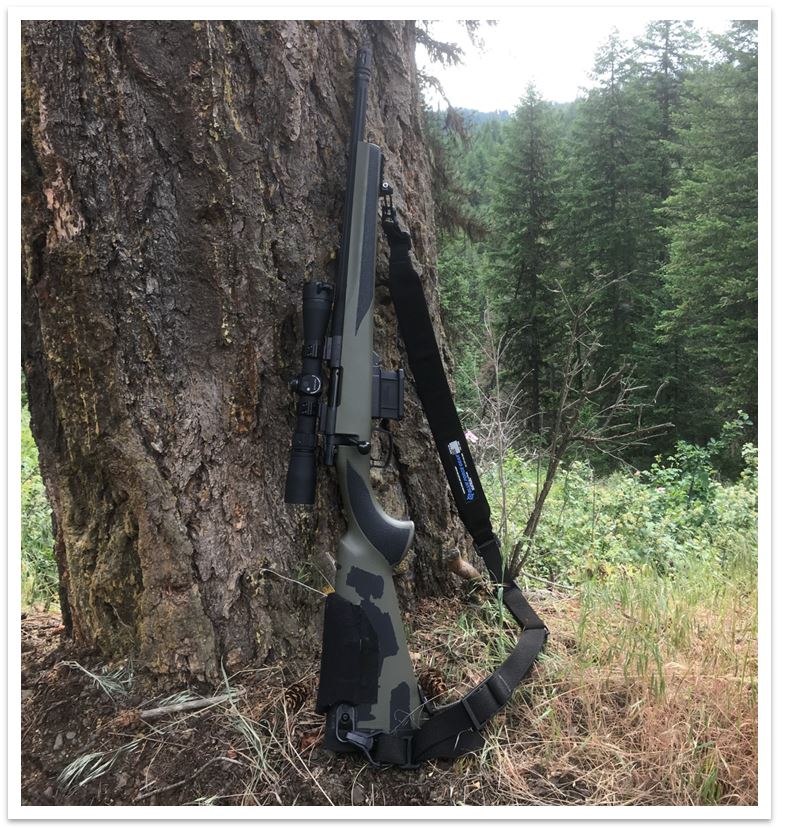

We romped around in the woods for a few hours, being purposefully abusive to the rifle with lots of drops and smacks. Many rounds later, the Howa's barrel was sizzling and the DIP bottom metal was running like a clock, letting the Howa Mini finally be the field-grade heirloom piece we always knew it could be. All three DIP accessories (the bottom metal itself, the mag catch, and the magazine baseplate) soaked up our roughhousing without complaint. We never had jams or failures of any kind, and we didn't accidentally release the magazine one single time.

Wrap Up

If your Howa Mini is ever going to live life outside the bench at the range, we highly recommend adding the DIP bottom metal to your shopping list. It is a rare accessory - a pure upgrade with no downside or caveat to its performance, other than cost (unless you consider adding 1.5 oz. a downside, in which case, go away). The DIP mag catch and magazine baseplate fall more into the realm of luxury items – extremely well-made and well-designed, but maybe not strictly necessary for the average shooter.

DIP doesn't just pump out aluminum versions of factory plastic parts - they're clearly real shooters and they build their parts to address actual problems with the factory design. Not only that, we found their build quality and fit to be superb, and their prices are reasonable given the billet-machined quality on offer.

DIP doesn't just pump out aluminum versions of factory plastic parts - they're clearly real shooters and they build their parts to address actual problems with the factory design. Not only that, we found their build quality and fit to be superb, and their prices are reasonable given the billet-machined quality on offer.

And that’s it. Happy shooting.

|

|

|