AR-15 Reliability: an in-depth look

Does any of this advice sound familiar?

Jokes aside, most of this advice is “forum knowledge”, i.e. advice that is assumed to be correct because the speaker has heard/read other people say that same advice many times. The speaker may also have some understanding of the mechanics underlying the fix, but the real validation of the advice is simply the fact that "everyone knows it." This didn’t used to be a problem because for a long time, most forum knowledge about AR-15s was pretty accurate. Today, however, things are getting dicier. The online gun community is getting a lot of new members looking for advice, and the AR-15 market is now huge and varied. Gone are the days when the commercial AR-15 had a "standard" layout using a mostly common set of parts, and you could say that if X is your problem, then Y is your solution, and didn’t really need more than a vague idea of why.

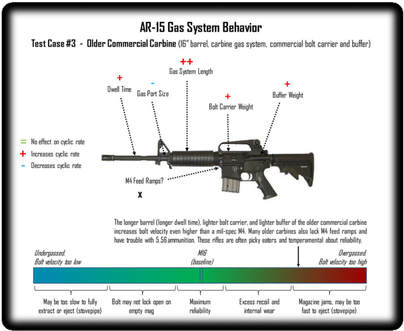

This article aims to help the reader understand the different factors (and there are many) affecting AR-15 reliability. To that end, it will begin with this article, a discussion of the different ways AR-15s are built (barrel length, gas port position, buffer weight, etc.) and how those features impact reliability. Part 2 of this article is visual rather than discussion-based, a series of “test cases” as shown below (or click the link to see them now) to showcase the reliability factors affecting some common AR-15 archetypes, such as a mil-spec M16, a “standard” commercial carbine, a short-barreled pistol, and others. The hope is that an AR-15 owner (or prospective owner) will be able to develop a plan for improving their particular rifle.

- Throw in a heavier buffer.

- Get a M16 bolt carrier.

- Get an adjustable gas block.

- NEVER USE AN ADJUSTABLE GAS BLOCK!!!!!!!!!!!!!!!!!!!!!!!!!!!

- Use this lube, it’s purple and that helps ensure reliable extraction.

- Just buy a Noveske.

- My AR that I built for $19.99 with free shipping has fired 20,000 rounds of steel-cased without failure and shoots MOA all day. YMMV.

Jokes aside, most of this advice is “forum knowledge”, i.e. advice that is assumed to be correct because the speaker has heard/read other people say that same advice many times. The speaker may also have some understanding of the mechanics underlying the fix, but the real validation of the advice is simply the fact that "everyone knows it." This didn’t used to be a problem because for a long time, most forum knowledge about AR-15s was pretty accurate. Today, however, things are getting dicier. The online gun community is getting a lot of new members looking for advice, and the AR-15 market is now huge and varied. Gone are the days when the commercial AR-15 had a "standard" layout using a mostly common set of parts, and you could say that if X is your problem, then Y is your solution, and didn’t really need more than a vague idea of why.

This article aims to help the reader understand the different factors (and there are many) affecting AR-15 reliability. To that end, it will begin with this article, a discussion of the different ways AR-15s are built (barrel length, gas port position, buffer weight, etc.) and how those features impact reliability. Part 2 of this article is visual rather than discussion-based, a series of “test cases” as shown below (or click the link to see them now) to showcase the reliability factors affecting some common AR-15 archetypes, such as a mil-spec M16, a “standard” commercial carbine, a short-barreled pistol, and others. The hope is that an AR-15 owner (or prospective owner) will be able to develop a plan for improving their particular rifle.

This test case is one of several in part 2 of this article series: AR-15 Reliability Test Cases .

They are helpful visual demonstrations of the gas system behavior associated with common AR-15 archetypes.

They are helpful visual demonstrations of the gas system behavior associated with common AR-15 archetypes.

Before we dive into the list of variables/factors, a quick bit of background:

The AR-15's firing cycle is affected by a great many factors, and arguably the biggest factor impacting reliability is the cyclic rate i.e. how fast the bolt opens and closes after a shot is fired. Too fast and the action might jam the magazine, or the extractor will lose its grip on the rim, or the bolt may catch the casing before it can eject (stovepipe), and so on. Too slow and the action might not have enough force to extract the casing, or can’t lock open on an empty magazine, or can’t open far enough to eject the fired casing (a different kind of stovepipe) and so on. The goal is a “goldilocks” zone; fast, but not too fast.

Most commonly-known “fixes” like heavier buffers or M4 feed ramps are meant to accommodate a cyclic rate that is too fast, because most AR-15s cycle too fast from the factory. However, in today’s world of 9” pistols and 14.5” mid-lengths, there are no guarantees, so let’s learn about all the variables that can contribute to an AR-15 cycling too fast, too slow, or just right. We’ll start with the widely known variables, listed in random order.

The AR-15's firing cycle is affected by a great many factors, and arguably the biggest factor impacting reliability is the cyclic rate i.e. how fast the bolt opens and closes after a shot is fired. Too fast and the action might jam the magazine, or the extractor will lose its grip on the rim, or the bolt may catch the casing before it can eject (stovepipe), and so on. Too slow and the action might not have enough force to extract the casing, or can’t lock open on an empty magazine, or can’t open far enough to eject the fired casing (a different kind of stovepipe) and so on. The goal is a “goldilocks” zone; fast, but not too fast.

Most commonly-known “fixes” like heavier buffers or M4 feed ramps are meant to accommodate a cyclic rate that is too fast, because most AR-15s cycle too fast from the factory. However, in today’s world of 9” pistols and 14.5” mid-lengths, there are no guarantees, so let’s learn about all the variables that can contribute to an AR-15 cycling too fast, too slow, or just right. We’ll start with the widely known variables, listed in random order.

Widely-known Variables Affecting AR-15 Reliability

Variable #1 - Gas System Length (Pistol, Carbine, Mid-length, Rifle)

A carbine AR-15 operates at almost 70% higher pressure than a rifle-length AR-15. This is because combustion gases cool and lose pressure as they move down the barrel, so the earlier on in the barrel that the gas port appears, the hotter and harder the gas is burning. Thus, a carbine AR-15’s bolt assembly slams back and forth much more quickly than a rifle-length AR-15’s bolt assembly, as it is receiving much more “push” from the greater pressure. The fast-moving bolt causes a “snappier” feel in the carbine's recoil and if the bolt moves too quickly, the window of time to extract, eject, and chamber a new round shrinks and the rate of malfunction increases sharply. In fact, development of the military M4 carbine revealed that the bolt assembly was moving so quickly that the magazine’s spring could not always push a new cartridge into position quickly enough, which led to the development of M4 feed ramps (essentially longer, more generous feed ramps to allow the magazine to keep up with the bolt).

In general, choosing the longest gas system that is practical for your rifle’s design is the best choice. But don’t forget to factor in variable #2 below.

A carbine AR-15 operates at almost 70% higher pressure than a rifle-length AR-15. This is because combustion gases cool and lose pressure as they move down the barrel, so the earlier on in the barrel that the gas port appears, the hotter and harder the gas is burning. Thus, a carbine AR-15’s bolt assembly slams back and forth much more quickly than a rifle-length AR-15’s bolt assembly, as it is receiving much more “push” from the greater pressure. The fast-moving bolt causes a “snappier” feel in the carbine's recoil and if the bolt moves too quickly, the window of time to extract, eject, and chamber a new round shrinks and the rate of malfunction increases sharply. In fact, development of the military M4 carbine revealed that the bolt assembly was moving so quickly that the magazine’s spring could not always push a new cartridge into position quickly enough, which led to the development of M4 feed ramps (essentially longer, more generous feed ramps to allow the magazine to keep up with the bolt).

In general, choosing the longest gas system that is practical for your rifle’s design is the best choice. But don’t forget to factor in variable #2 below.

Variable #2 - Dwell Time (gas port location relative to barrel length)

There needs to be sufficient distance between the gas port and the muzzle of the barrel. The pressure used to cycle the action disappears once the bullet has left the barrel and broken the seal, so the period of time between the bullet passing the gas port and then leaving the barrel, known as dwell time, needs to be sufficiently long to fully exercise the bolt’s opening stroke. If the gas port is too close to the muzzle, you can encounter almost insurmountable short-cycling (undergassing). If the gas port is too far, your rifle will be overgassing. Overgassing is much more common than undergassing, so we’ll talk about that first.

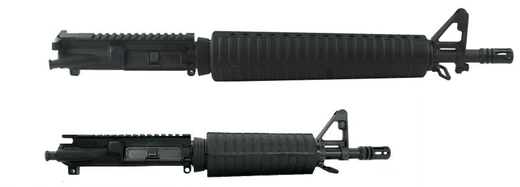

Overgassing as a result of dwell time isn’t a huge concern for the machine itself, as the AR action gathers only the pressure that it needs and then vents excess gas through the two ports on the right side of the bolt carrier (see image at right).

From a human standpoint, though, excess gas as a result of dwell time can get unpleasant. Although the bolt assembly is safe from excess pressure, gas will continue to spray into the receiver from the gas tube after the BCG has unlocked and moved rearward, bringing soot, heat, and other unpleasantries. Most of that mess will leave the receiver through the ejection port, but the AR receiver happens to have a hole for the charging handle right in front of your nose which may occasionally squirt a small, hot fart right into your face. This problem is especially pronounced with a suppressor, which acts like a dwell time enhancer.

There needs to be sufficient distance between the gas port and the muzzle of the barrel. The pressure used to cycle the action disappears once the bullet has left the barrel and broken the seal, so the period of time between the bullet passing the gas port and then leaving the barrel, known as dwell time, needs to be sufficiently long to fully exercise the bolt’s opening stroke. If the gas port is too close to the muzzle, you can encounter almost insurmountable short-cycling (undergassing). If the gas port is too far, your rifle will be overgassing. Overgassing is much more common than undergassing, so we’ll talk about that first.

Overgassing as a result of dwell time isn’t a huge concern for the machine itself, as the AR action gathers only the pressure that it needs and then vents excess gas through the two ports on the right side of the bolt carrier (see image at right).

From a human standpoint, though, excess gas as a result of dwell time can get unpleasant. Although the bolt assembly is safe from excess pressure, gas will continue to spray into the receiver from the gas tube after the BCG has unlocked and moved rearward, bringing soot, heat, and other unpleasantries. Most of that mess will leave the receiver through the ejection port, but the AR receiver happens to have a hole for the charging handle right in front of your nose which may occasionally squirt a small, hot fart right into your face. This problem is especially pronounced with a suppressor, which acts like a dwell time enhancer.

|

Additionally, not all of the filth from excessive dwell time makes it out of the various holes in the receiver; some of it stays put as grime building up on your internals. Eventually, this buildup will cause malfunctions, but as long as your AR is well-lubed this will still take hundreds if not thousands of rounds (the "filthy 14" article by S.W.AT. magazine chronicled a well-lubed carbine that fired over 30,000 rounds with only one cleaning, and experienced only a handful of malfunctions). Grime buildup may sound scary, but outside of suppressor usage it’s barely worth mentioning. The real concern for overgassing as a result of dwell time is simply human discomfort (although overgassing via other means, like a gas port that is too large, can absolutely cause excessive wear or damage to the firearm).

Now that we’ve discussed overgassing, let’s switch to undergassing. Unlike overgassing, undergassing as a result of dwell time can cause immediate, consistent reliability problems. The energy of the combustion gases siphoned from the barrel has a lot of jobs: rotate the bolt, extract the case, throw the bolt backward, and more. If the system isn’t spending enough time building pressure because of insufficient dwell time, it’s hard to generate enough energy to do all of that. Undergassing as a result of dwell time is tough to correct, but luckily it is fairly rare, seen only in some AR pistols, SBRs and the occasional “dissipator”-style rifle. |

Stoner’s original design for the AR was top-charging via a handle under the carry handle. The familiar T-shaped charging handle (and the hole in the back of the receiver that causes suppressor users so much grief) was added at the military’s request.

|

Solutions for a rifle that is undergassed as a result of dwell time are few and difficult. Number one is to enlarge the gas port, but this can only be opened up so far. Although the amount of time the system is pressurized will be limited by the dwell time, the system is only meant to take so much pressure to begin with, so if give yourself a big gaping hole of a gas port, your gun may just start flying apart the next time you fire a round that’s loaded a little bit hotter than most. Alternatively, a suppressor acts much like a dwell time enhancer, aiding in reliability. If you aren’t keen on the legal hassles or cost of a suppressor, some linear compensators feature internal chambers or multi-piece designs that capture gas briefly during firing, enhancing dwell time. The downside of these compensators is that they are typically expensive, heavy, and long, often adding 3-4 inches to your barrel length, which sometimes defeats the purpose of the shortened barrels found on pistols, SBRs, and dissipators. See variable #7.

Variable #3 - Gas Port Size

The larger the gas port, the more push is applied to the action and the faster the action will cycle. As you might expect, hot-burning carbine gas systems typically have smaller gas ports (around 0.0625”) to limit how hard they push the action, and cool-running rifle-length gas systems have larger gas ports (around 0.0935”). Unfortunately, the margin for error is much higher with a smaller gas port; it’s better to hit the action with a big whallop of cool, low-pressure gas than a tiny spurt of hot, high-pressure gas. This concern is especially pronounced with low-quality ammunition, which often generates weak or inconsistent pressure.

There is very little standardization in the industry regarding gas port size and very few vendors will be able to tell you the size of a barrel’s gas port. For the most part, you have to take what you’re given, but smaller gas ports can be enlarged, and gas ports that are too large can have their flow restricted with an adjustable gas block.

Variable #4 - Buffer Weight

The buffer’s primary purpose is to absorb recoil energy, but its secondary function is to allow easy changes to the cyclic rate of the gun. Since the buffer is easy to replace, it’s one of the easiest ways to adjust push and drag in your individual action, so there are a variety of buffer weights available commercially. For a long time, most commercial 16” carbines have used a 3.0oz buffer housing three steel weights inside. This 3.0oz commercial buffer is cheap, but it’s not ideal for an overgassed commercial carbine. The original rifle buffer was twice as long and weighed 5.2oz, and the short, light 3.0oz carbine buffer was intended for the original “commando” short-barreled AR-15s, which had very short barrels (around 11”) that undergassed the action. Reducing the buffer weight helped these anemic gas systems cycle successfully, while longer-barreled carbines often benefit from buffer that is as-heavy or heavier than the standard rifle buffer, since their actions are being driven harder by the high-pressure gas of the shortened gas system.

This problem is exacerbated in commercial carbines, which usually have a 16” barrel, increasing dwell time over the 14.5” barrel of military guns, plus a slightly lighter bolt carrier than the military standard, as commercial carriers are machined without certain features that military bolt carriers need to fire in full-auto. Thus we have the H1, H2, H3, and 9mm carbine buffers, some of which outweigh the original rifle buffer dramatically even though they are half the size. This is possible through the use of tungsten weights instead of steel weights, but tungsten is much more expensive than steel. So, many manufacturers use the cheaper 3.0oz buffer (since the gun will run “okay” with it) and leave it to aftermarket to sell gun owners the correct, heavyweight buffers that their carbines need.

Adding a heavier buffer is a fairly easy and cheap way to add drag to the action, so it’s a common fix, but it’s only a fix if your rifle is overgassed. Adding a heavier buffer to an undergassed rifle (like a SBR or pistol) will only make the problem worse, but many gun owners do so anyway due to the overwhelming number of people telling them that the guaranteed fix for a finicky AR is a heavier buffer.

The buffer’s primary purpose is to absorb recoil energy, but its secondary function is to allow easy changes to the cyclic rate of the gun. Since the buffer is easy to replace, it’s one of the easiest ways to adjust push and drag in your individual action, so there are a variety of buffer weights available commercially. For a long time, most commercial 16” carbines have used a 3.0oz buffer housing three steel weights inside. This 3.0oz commercial buffer is cheap, but it’s not ideal for an overgassed commercial carbine. The original rifle buffer was twice as long and weighed 5.2oz, and the short, light 3.0oz carbine buffer was intended for the original “commando” short-barreled AR-15s, which had very short barrels (around 11”) that undergassed the action. Reducing the buffer weight helped these anemic gas systems cycle successfully, while longer-barreled carbines often benefit from buffer that is as-heavy or heavier than the standard rifle buffer, since their actions are being driven harder by the high-pressure gas of the shortened gas system.

This problem is exacerbated in commercial carbines, which usually have a 16” barrel, increasing dwell time over the 14.5” barrel of military guns, plus a slightly lighter bolt carrier than the military standard, as commercial carriers are machined without certain features that military bolt carriers need to fire in full-auto. Thus we have the H1, H2, H3, and 9mm carbine buffers, some of which outweigh the original rifle buffer dramatically even though they are half the size. This is possible through the use of tungsten weights instead of steel weights, but tungsten is much more expensive than steel. So, many manufacturers use the cheaper 3.0oz buffer (since the gun will run “okay” with it) and leave it to aftermarket to sell gun owners the correct, heavyweight buffers that their carbines need.

Adding a heavier buffer is a fairly easy and cheap way to add drag to the action, so it’s a common fix, but it’s only a fix if your rifle is overgassed. Adding a heavier buffer to an undergassed rifle (like a SBR or pistol) will only make the problem worse, but many gun owners do so anyway due to the overwhelming number of people telling them that the guaranteed fix for a finicky AR is a heavier buffer.

Variable #5 - Ammunition Quality

We know, we know… nobody wants to hear this. The good news is that you can still feed your rifle crappy ammo, you just have to fix other problems to give yourself a nice big envelope of “healthy functioning”. An AR that is a picky eater is typically unbalanced in some way, so you can treat that pickiness as a symptom that there’s some work to be done. But, if you’ve done everything you can to fix your gun and it still “ain’t right” (and this will often be the case with exotic designs like SBRs and pistols), you may just need to pay a little more to find a brand of quality brass that your rifle likes.

Ammunition quality is particularly detrimental to reliability in rifles with shorter gas systems (carbine and pistol) because low quality ammunition tends to put out pressure that is weak and/or inconsistent, and short rifles tend to have small gas ports and/or reduced dwell time (see variable #1 and #2 above), so they need a powerful, consistent combustion to function reliably.

We know, we know… nobody wants to hear this. The good news is that you can still feed your rifle crappy ammo, you just have to fix other problems to give yourself a nice big envelope of “healthy functioning”. An AR that is a picky eater is typically unbalanced in some way, so you can treat that pickiness as a symptom that there’s some work to be done. But, if you’ve done everything you can to fix your gun and it still “ain’t right” (and this will often be the case with exotic designs like SBRs and pistols), you may just need to pay a little more to find a brand of quality brass that your rifle likes.

Ammunition quality is particularly detrimental to reliability in rifles with shorter gas systems (carbine and pistol) because low quality ammunition tends to put out pressure that is weak and/or inconsistent, and short rifles tend to have small gas ports and/or reduced dwell time (see variable #1 and #2 above), so they need a powerful, consistent combustion to function reliably.

Variable #6 - Bolt Carrier Weight

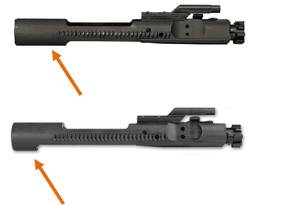

Military bolt carriers (often called M16 bolt carriers) are slightly heavier than most commercial bolt carriers, as commercial bolt carriers are machined without features that would allow their use in full-auto rifles. Today, it is widely accepted that possessing a “full auto” bolt carrier is perfectly legal in a civilian semi-auto rifle, but some manufacturers continue to use commercially-cut bolt carriers.

The lighter bolt carrier is easier to for combustion gases to push around, so the action has a little more “push” than it normally would and the action cycles a bit too fast. Swapping out the bolt carrier for a M16 bolt carrier will add a little bit of drag and help many carbines cycle at a healthier velocity.

Military bolt carriers (often called M16 bolt carriers) are slightly heavier than most commercial bolt carriers, as commercial bolt carriers are machined without features that would allow their use in full-auto rifles. Today, it is widely accepted that possessing a “full auto” bolt carrier is perfectly legal in a civilian semi-auto rifle, but some manufacturers continue to use commercially-cut bolt carriers.

The lighter bolt carrier is easier to for combustion gases to push around, so the action has a little more “push” than it normally would and the action cycles a bit too fast. Swapping out the bolt carrier for a M16 bolt carrier will add a little bit of drag and help many carbines cycle at a healthier velocity.

Variable #7 - Muzzle Devices

Most muzzle devices do not impact the action to a substantial extent, but there are two exceptions: suppressors and certain types of linear compensator (notable examples include the Noveske KX3 and the various Russian AK-U muzzle boosters). Both can act as dwell time enhancers, which can be a boon to a gun that is undergassing, or a detriment to a gun that is overgassing.

Most muzzle devices do not impact the action to a substantial extent, but there are two exceptions: suppressors and certain types of linear compensator (notable examples include the Noveske KX3 and the various Russian AK-U muzzle boosters). Both can act as dwell time enhancers, which can be a boon to a gun that is undergassing, or a detriment to a gun that is overgassing.

Variable #8 - Tolerances Within Individual Rifles

Sometimes, there’s just no accounting for hard use or poor manufacturing. If your gun just isn’t working correctly and you can’t pinpoint the problem, it may be time to tear down and rebuild just to make sure everything is correct. Gas tubes can get clogged, gas keys can loosen or be misaligned, chambers can have machine marks that make extraction difficult, and so on. To be frank, this is where a good gunsmith comes in handy.

Sometimes, there’s just no accounting for hard use or poor manufacturing. If your gun just isn’t working correctly and you can’t pinpoint the problem, it may be time to tear down and rebuild just to make sure everything is correct. Gas tubes can get clogged, gas keys can loosen or be misaligned, chambers can have machine marks that make extraction difficult, and so on. To be frank, this is where a good gunsmith comes in handy.

Less Commonly-known Variables Affecting AR-15 Reliability

(less common does not always mean less important)

(less common does not always mean less important)

Variable #9 - M4 Feed Ramps vs. Rifle Feed Ramps

All AR-15s have feed ramps that allow rounds from the magazine to move smoothly to the chamber, and these days, almost all have the improved M4 feed ramps, so this isn't a common troubleshooting point anymore. The story is that in the original M16, the bolt moved slowly enough that these ramps only needed to be cut into the barrel extension. As Colt tried to engineer the shorter M4, the bolt’s velocity climbed much higher than the original M16, and it was determined that longer feed ramps would help the magazine keep up with the bolt and ensure successful feeding. To that end, feed ramps were cut into the receiver as well as the barrel extensions, giving a longer and gentler slope to ensure successful feeding. Additionally, the angle of the feed ramps was changed to be more shallow.

A rifle with a high cyclic rate will struggle without M4 feed ramps. There is no downside to having M4 feed ramps unless your receiver has them and your barrel extension does not, so it is best to ensure that both your barrel extension and your receiver are cut for them. Manufacturers are generally good about matching their barrels and receivers in this way, but if you’re ordering parts individually for a build, it’s something to keep your eye on.

All AR-15s have feed ramps that allow rounds from the magazine to move smoothly to the chamber, and these days, almost all have the improved M4 feed ramps, so this isn't a common troubleshooting point anymore. The story is that in the original M16, the bolt moved slowly enough that these ramps only needed to be cut into the barrel extension. As Colt tried to engineer the shorter M4, the bolt’s velocity climbed much higher than the original M16, and it was determined that longer feed ramps would help the magazine keep up with the bolt and ensure successful feeding. To that end, feed ramps were cut into the receiver as well as the barrel extensions, giving a longer and gentler slope to ensure successful feeding. Additionally, the angle of the feed ramps was changed to be more shallow.

A rifle with a high cyclic rate will struggle without M4 feed ramps. There is no downside to having M4 feed ramps unless your receiver has them and your barrel extension does not, so it is best to ensure that both your barrel extension and your receiver are cut for them. Manufacturers are generally good about matching their barrels and receivers in this way, but if you’re ordering parts individually for a build, it’s something to keep your eye on.

Variable #10 - Recoil Spring Length, Type, and Tension

The stiffness of the action spring directly affects cyclic rate, and there is a surprising amount of variation in action spring design. Action springs come in different lengths, can be made from different types of steel, can be made from rounded wire or flat wire, and can also just wear out over time. All or any of the previously listed factors can have an unexpected effect on your cyclic rate, so pay attention to your action spring when diagnosing a troublesome AR. When building, a tried and true setup is a standard stainless steel spring of 10.5" length of carbine buffer tubes and 12.75" length for rifle buffer tubes, +/- 0.5" in both cases. Check your recoil spring against these specs and if it doesn’t match up, you may have found a weak spot in your AR. When seeking a replacement recoil spring, feel free to experiment with fancier materials or designs, but be aware of your rifle’s baseline cyclic rate when doing so.

The stiffness of the action spring directly affects cyclic rate, and there is a surprising amount of variation in action spring design. Action springs come in different lengths, can be made from different types of steel, can be made from rounded wire or flat wire, and can also just wear out over time. All or any of the previously listed factors can have an unexpected effect on your cyclic rate, so pay attention to your action spring when diagnosing a troublesome AR. When building, a tried and true setup is a standard stainless steel spring of 10.5" length of carbine buffer tubes and 12.75" length for rifle buffer tubes, +/- 0.5" in both cases. Check your recoil spring against these specs and if it doesn’t match up, you may have found a weak spot in your AR. When seeking a replacement recoil spring, feel free to experiment with fancier materials or designs, but be aware of your rifle’s baseline cyclic rate when doing so.

Variable #11 - Magazine Capacity and Partial Loading

A fully loaded magazine exerts quite a bit of pressure on the AR-15's bolt; anyone who has loaded a full mag on a closed bolt knows this. This causes a small amount of drag on the action, usually not enough to cause a malfunction, but if your action already has a bit too much drag, a fully loaded magazine can push it over the edge, especially if the action is dirty or you happened to get a round with a lower charge than usual.

Also note how frequently you fully load your magazine. A partially loaded magazine imparts much less drag than a full loaded magazine, so if you do your range plinking and sight-ins with only ten or fifteen rounds loaded into your high capacity mag, it’s possible your reliability will be affected when you start slamming home loaded 30-round mags at a shooting match.

Magazine pressure alone will not usually cause malfunctions, but it can stack with other coincident factors elsewhere in the gun to contribute to unreliability.

A fully loaded magazine exerts quite a bit of pressure on the AR-15's bolt; anyone who has loaded a full mag on a closed bolt knows this. This causes a small amount of drag on the action, usually not enough to cause a malfunction, but if your action already has a bit too much drag, a fully loaded magazine can push it over the edge, especially if the action is dirty or you happened to get a round with a lower charge than usual.

Also note how frequently you fully load your magazine. A partially loaded magazine imparts much less drag than a full loaded magazine, so if you do your range plinking and sight-ins with only ten or fifteen rounds loaded into your high capacity mag, it’s possible your reliability will be affected when you start slamming home loaded 30-round mags at a shooting match.

Magazine pressure alone will not usually cause malfunctions, but it can stack with other coincident factors elsewhere in the gun to contribute to unreliability.

Variable #12 - Buffer Construction (dead-blow vs solid)

A quality buffer is made from turned aluminum, not plastic, and contains several tubular weights, separated by spacers. These weights are somewhat loose inside the buffer, and you should hear them clack back and forth when you shake the buffer. This is important because those clacking weights act like a dead-blow hammer, helping mitigate bolt bounce when the AR-15 action closes by adding a second impact to the closing stroke as the weights inside the buffer “clack” forward after being pushed to the rear by inertia. Cheap buffers may use lead shot to make a buffer that is the correct weight, but lacks the “clacking” effect and contributes to excessive bolt bounce. Also avoid 9mm buffers, which use rubber weights instead of steel or tungsten. Finally, some brands of premium specialty buffers use tungsten shot or powder, which may sound exotic, but many still lack the dead-blow “clacking” effect and should be avoided.

A quality buffer is made from turned aluminum, not plastic, and contains several tubular weights, separated by spacers. These weights are somewhat loose inside the buffer, and you should hear them clack back and forth when you shake the buffer. This is important because those clacking weights act like a dead-blow hammer, helping mitigate bolt bounce when the AR-15 action closes by adding a second impact to the closing stroke as the weights inside the buffer “clack” forward after being pushed to the rear by inertia. Cheap buffers may use lead shot to make a buffer that is the correct weight, but lacks the “clacking” effect and contributes to excessive bolt bounce. Also avoid 9mm buffers, which use rubber weights instead of steel or tungsten. Finally, some brands of premium specialty buffers use tungsten shot or powder, which may sound exotic, but many still lack the dead-blow “clacking” effect and should be avoided.

Variable #13 - Extractor O-rings and Extractor Inserts

The spring-loaded extractor of the AR-15 can slip off of the rim of the cartridge during extraction. The Close Combat Armament Center conducted a fascinating study about extractor lift and concluded that extractor lift occurs when the bolt is intially thrown violently backward after unlocking. Even with the extractor lifted up off the case rim, the casing will "coast" along behind the bolt face as long as residual chamber pressure holds the case firmly against the bolt face, allowing the extractor time to succesfully re-engage the case rim.

However, minimizing the amount of time that the extractor lifts off of the case rim is obviously a priority, so an o-ring is sometimes inserted under the extractor and around the extractor spring, and a plastic insert under the extractor spring itself. These parts are thought to minimize the vibrations and spring rebound that allow the extractor to lift off of the case rim. Opinions vary as to how critical these parts are, but they are very cheap and have never been conclusively proven to harm the action. Furthermore, most if not all quality bolt carrier groups come with at least one of these items installed, so if you're having issues with extraction, f*&$ it, why not?

The spring-loaded extractor of the AR-15 can slip off of the rim of the cartridge during extraction. The Close Combat Armament Center conducted a fascinating study about extractor lift and concluded that extractor lift occurs when the bolt is intially thrown violently backward after unlocking. Even with the extractor lifted up off the case rim, the casing will "coast" along behind the bolt face as long as residual chamber pressure holds the case firmly against the bolt face, allowing the extractor time to succesfully re-engage the case rim.

However, minimizing the amount of time that the extractor lifts off of the case rim is obviously a priority, so an o-ring is sometimes inserted under the extractor and around the extractor spring, and a plastic insert under the extractor spring itself. These parts are thought to minimize the vibrations and spring rebound that allow the extractor to lift off of the case rim. Opinions vary as to how critical these parts are, but they are very cheap and have never been conclusively proven to harm the action. Furthermore, most if not all quality bolt carrier groups come with at least one of these items installed, so if you're having issues with extraction, f*&$ it, why not?

Variable #14 - Hammer Spring Tension

The bolt pushes the hammer down on its opening stroke, so the spring tension holding the hammer upright must be overcome by the bolt as it travels backward. A weaker hammer spring is an easy way to lighten the trigger’s pull weight, but also increases cyclic rate slightly, as there is less force dragging on the bolt as it opens. Conversely, using a stiffer hammer spring to ensure detonation of old, hard milsurp primers will slow the cyclic rate slightly, as the bolt group needs more force to overcome the stiffer spring.

Hammer spring tension alone will not usually cause malfunctions, but it can stack with other coincident factors elsewhere in the gun to contribute to unreliability.

The bolt pushes the hammer down on its opening stroke, so the spring tension holding the hammer upright must be overcome by the bolt as it travels backward. A weaker hammer spring is an easy way to lighten the trigger’s pull weight, but also increases cyclic rate slightly, as there is less force dragging on the bolt as it opens. Conversely, using a stiffer hammer spring to ensure detonation of old, hard milsurp primers will slow the cyclic rate slightly, as the bolt group needs more force to overcome the stiffer spring.

Hammer spring tension alone will not usually cause malfunctions, but it can stack with other coincident factors elsewhere in the gun to contribute to unreliability.

Variable #15 - Lightweight Internals

From skeletonized bolt groups to hollow buffers, the commercial market offers many high performance parts for you AR. If the installer can tune your action correctly, these parts can reduce recoil dramatically and give the shooter an edge over the factory-configured rifles, but some shooters purchase and install these components without understanding the intent behind their design. In most cases, lightweight or skeletonized internals are intended to be used with an adjustable gas block or other regulator to avoid increasing bolt velocity to unhealthy levels. Installing these components without being able to tune the gas system is not recommended.

From skeletonized bolt groups to hollow buffers, the commercial market offers many high performance parts for you AR. If the installer can tune your action correctly, these parts can reduce recoil dramatically and give the shooter an edge over the factory-configured rifles, but some shooters purchase and install these components without understanding the intent behind their design. In most cases, lightweight or skeletonized internals are intended to be used with an adjustable gas block or other regulator to avoid increasing bolt velocity to unhealthy levels. Installing these components without being able to tune the gas system is not recommended.

Variable #16 - 5.56 vs .223 Chambering

This is another issue that was common a few years ago, but rarely seen today. 5.56 and .223 rounds are identical in their dimensions i.e. it is impossible to tell them apart just by measuring them. However, 5.56 rounds are usually loaded a bit hotter (charged with more powder for a higher velocity) than .223 rounds, so 5.56 chambers are cut with a longer leade. A chamber leade is the distance from the cartridge mouth to the rifling, and a longer leade lets you safely fire more powerful ammunition at a slight cost to your ultimate accuracy. Years ago, commercial rifles were trying to maximize accuracy with commercial ammunition (.223) so they often used a .223 chamber and leade (many target models of AR-15, Ruger Mini-14, and other .223 rifles still do this today). As cheap 5.56 ammunition became more available, however, people started shooting it through their .223 chambered rifles, and the shorter leade generated too much pressure, leading to stuck cases, blown primers, and other nastiness. Today, virtually all manufacturers use chambers that can fire either 5.56 or .223 reliably, and the accuracy loss incurred by the longer leade is VERY difficult to notice. However, a quick check of the barrel stampings or a call to the manufacturer is a low-cost troubleshooting step for a finicky AR.

This is another issue that was common a few years ago, but rarely seen today. 5.56 and .223 rounds are identical in their dimensions i.e. it is impossible to tell them apart just by measuring them. However, 5.56 rounds are usually loaded a bit hotter (charged with more powder for a higher velocity) than .223 rounds, so 5.56 chambers are cut with a longer leade. A chamber leade is the distance from the cartridge mouth to the rifling, and a longer leade lets you safely fire more powerful ammunition at a slight cost to your ultimate accuracy. Years ago, commercial rifles were trying to maximize accuracy with commercial ammunition (.223) so they often used a .223 chamber and leade (many target models of AR-15, Ruger Mini-14, and other .223 rifles still do this today). As cheap 5.56 ammunition became more available, however, people started shooting it through their .223 chambered rifles, and the shorter leade generated too much pressure, leading to stuck cases, blown primers, and other nastiness. Today, virtually all manufacturers use chambers that can fire either 5.56 or .223 reliably, and the accuracy loss incurred by the longer leade is VERY difficult to notice. However, a quick check of the barrel stampings or a call to the manufacturer is a low-cost troubleshooting step for a finicky AR.

WHEW!

So that’s the majority of the factors that affect your AR-15’s cyclic rate, and how they do it. To see how these factors affect some common AR-15 builds, check out the AR-15 Reliability Test Cases article. And the next time someone asks why their AR is jamming, don’t just say “use a heavier buffer”.

So that’s the majority of the factors that affect your AR-15’s cyclic rate, and how they do it. To see how these factors affect some common AR-15 builds, check out the AR-15 Reliability Test Cases article. And the next time someone asks why their AR is jamming, don’t just say “use a heavier buffer”.

Articles you might also like:

|

|

|